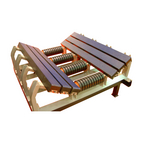

Impact Bars

The impact bed is used in the place of conveyor overflows, where the impact height and size of the material can cause damage to the conveyor belt as a result of the material falling against the transport roller and the subsequent occurrence of a breakthrough. Furthermore, also in the case of insufficient sealing of the side lines due to bending of the conveyor belt in the gaps between the stools of the transport rollers.

For both of these cases, an impact bed is ideal, which consists of impact bars of various sizes and an assembly bench or roller adapters.

Due to its design, the impact bars ideally support the conveyor belt thanks to the aluminum T profile, which is vulcanized in a layer of rubber with a hardness of 60 ° ShA with excellent shock absorption, this layer is finished with a sheet of polyethylene (PE 1000 UHMW) with a low koe.

The impact bars are attached to the conveyor using special chairs or to existing roller chairs using adapters. The necessary quantity and construction of supporting chairs is chosen according to the belt load and transport capacity. The connection is made with T screws of several sizes, the head of which is inserted into the aluminum profile of the impact bar.

Advantages of the system:

- simple installation and the possibility of variable impact arrangement

- cushions impacts caused by falling material

- increases the service life of the conveyor belt and conveyor components

- the belt does not sag when loaded with falling material (less dustiness)

- guides the conveyor belt against turning sideways

Handling particularly heavy bulk materials such as minerals or cement requires additional conveyor accessories to ensure functionality and durability. Bumper bars are auxiliary devices designed to be placed under conveyor loading points to prevent damage and misalignment of the belt and to prevent material spillage.

Our products are made of high-quality rubber and polyethylene. The former has shock-absorbing properties to absorb the impact of material falling onto the belt during loading operations. The latter provides the necessary low friction so that the belt can run smoothly with limited additional energy consumption.

The added value of our impact bars is their availability and flexibility. First, the use of the above materials ensures a long service life, which reduces maintenance time and costs. Then supplied fixing screws allow easy, fast and safe installation on belt conveyors. Finally, our company can design and manufacture impact bars for any belt type, width and pitch angle, ensuring easy conversion from traditional impact systems if required.

Ján Plavák

Tel.: +421 37 7777 923

Mobile: +421 903 575 748

Fax: +421 37 7777 928

Email:jpl@bibus.sk