Joulin

The Joulin company, which belongs to the Piab group, is the inventor of the foam vacuum gripper and the manufacturer of innovative handling systems for more than 60 years.

From a simple foam vacuum gripper integrated into your palletizing robots to a complete turnkey stacker for the woodworking industry.

Applications and products for various industrial applications:

- Handling of cartons

- Handling barrels, buckets and cans

- Handling of glass cups

- Handling of packaged products

- Bag handling

- Handling different types of bricks

More info: https://www.joulin.com/all-industries/applications.html

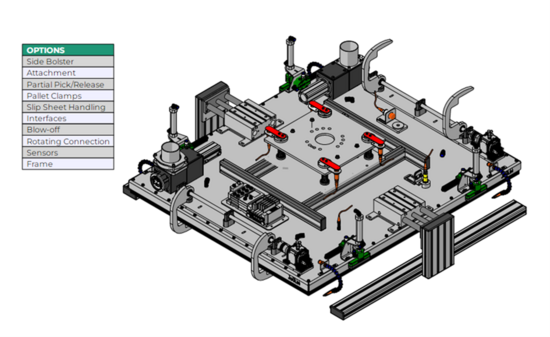

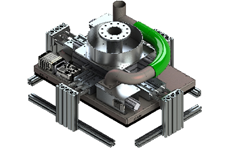

Customized foam vacuum gripper

CONCEPT

Custom design to suit your specific application

Pick up all products without modification

The grip force remains constant for individual parts or the entire layer

STEPS

Analysis of your specifications

Tests based on your samples

Design and manufacture of a custom-made gripper

ADVANTAGES

Complete EOAT design by Joulin

Guarantee of complete functionality

Benefit from 60 years of custom gripper experience

Low maintenance

Designed with Griptech™ and Wave System™

MORE OPTIONS

- Additional devices for robots

- Side supports

- Electrical installation and field bus

Possibility of installation and start-up on site

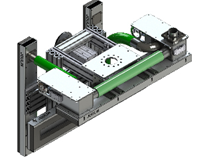

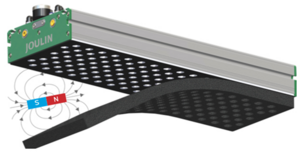

CONCEPT

Foam with magnetic adhesion

Quick and easy removal of foam from the gripper

Easy installation on existing grippers

It reduces maintenance time and costs

No glue to remove when changing the foam

ADVANTAGES

Easy access to the gripper for maintenance and cleaning

It can be removed / replaced an unlimited number of times

A reusable independent filter for dusty environments is available

SIMPLE ADJUSTMENT

Adaptable to all brands of existing grippers

All foam styles / brands

Simply clean and replace the filter by removing the magnetic foam

Foam/foam

A suitable foam is a guarantee of efficient handling and really economical handling.

Porosity, elasticity, durability, maintenance costs

Joulin quality

Expert knowledge and cutting locations in Europe and the USA allow us to guarantee quality at the best price and the most efficient service.

The most suitable foam/foam:

We know how to define and manufacture the most suitable foam for your gripper and the products to be handled.

Universal foam with fine pores

Foam used for open-top or delicate products.

Very durable and has a low memory.

For wood, cartons, cans, barrels, cans, pressed parts, perforated parts, etc...

Universal foam with large pores

The most frequently used material.

It offers softness, durability and low memory.

Many thicknesses available.

For wood, cartons, buckets, cans, barrels, pressed parts, perforated parts, etc...

Universal thick foam

Durable high density foam.

Resists abrasion and cutting from rough materials.

Reduces long-term operating costs.

For bricks, cinder blocks, frozen products, abrasive materials, etc...

Oil-resistant foam

For oily materials

For machining parts, steel cylinders, etc...

High density foam

resistant to protruding sharp edges of products.

Long service life between replacements.

The overall surface of the product must be sufficiently flat.

For can layers, cans, open top products, etc.

Standard or custom production of foams

For all gripper designs and brands

Slavomír Brath

Tel: +421 37 7777 950

Mobile: +421 903 282 393

Fax: +421 37 7777 969

Email:sbr@bibus.sk