Color and ink weighing technology from FMS.

For years, FMS has supplied the industry with accurate and durable components and systems for tension measurement and belt guidance. In addition, FMS offers a solution to a task that repeatedly poses great challenges to users and OEMs (especially flexo, gravure and offset printing machines). The solution concerns accurate measurement of ink and ink consumption, focusing on:

- continuous measurement of the smallest pumping quantities,

- determination and optimization of the cost of paint per order or batch,

- as well as early detection of leaks in the pipeline system.

FMS-platform SCALE. This is the name of a highly accurate and modular scale for weighing paints or inks, developed by the FMS engineering team, taking into account the above requirements.

The latest product from FMS offers you the following benefits, among others:

- Accurate measurement results

- With resolution from 5g

- The easiest integration

- To your PLC with our proven amplifiers with Ethernet interface

- Robustness and durability

- Torsionally rigid galvanized steel frame with stainless steel cover

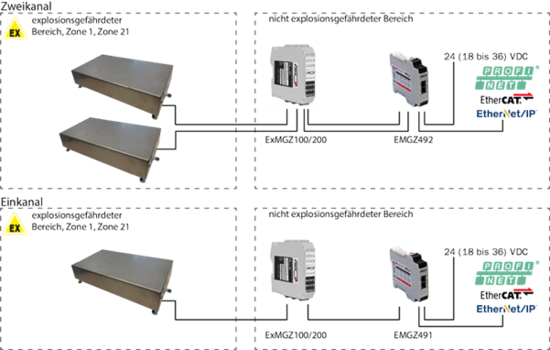

- Security

- Suitable for use in potentially explosive atmospheres (with ExMGZ100/200)

Good to know:

- Our modular design is fully suitable for industrial use. Flexible platform dimensions and different rated loads are the perfect and cost-effective solution - even for your printing machines.

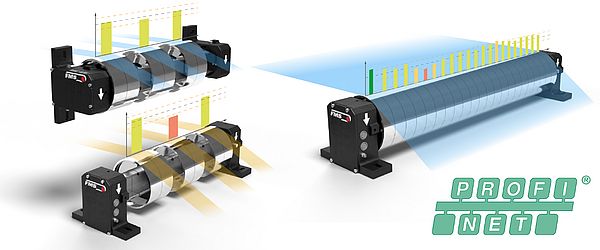

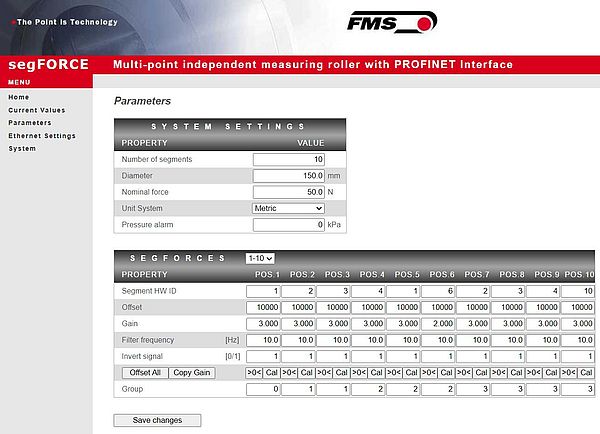

FMS-segFORCE now with PROFINET connection.

With the PROFINET interface, FMS-segFORCE now offers the perfect possibility to connect your PLC or other systems for measuring or collecting machine data. The PROFINET interface is part of the standard delivery and is immediately available. Additional Ethernet protocols are in development and will be available soon.

Another innovation is the integrated web interface. This makes configuration incredibly easy. Connect a laptop or PC to the measuring cylinder via a peer-to-peer connection. Run the configuration through the browser and make the necessary changes.

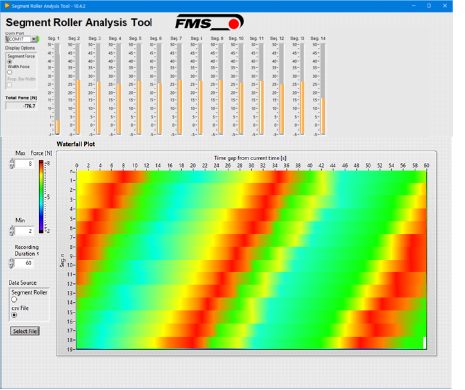

Optionally we also offer our software package FMS-segFORCE. Clear display of measured data. Data recording for analysis and optimization.

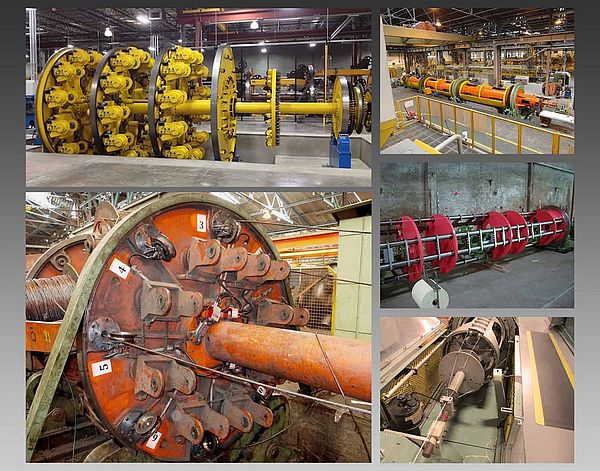

Telemetric monitoring of wire tension in rotating machines RTM X42 from FMS Force Measuring Systems AG

Are you looking for a modular system for monitoring the tension of wire and cage ropes? Should it continuously measure wire tension? Do you expect easy integration into existing machine control? Request a quote for the RTM X42 system.

With our system extensions, you can gradually expand the basic function by simply monitoring the source voltage to a comprehensive monitoring system and an integrated system of complete voltage control in a closed loop.

RTM X42.CC Control Center - System extension for the RTM X42 monitoring system with main control and FMS monitoring and control software

Features:

- Displays measured values and other relevant parameters

- Generate quality reports for the internal or customer knowledge base

- Recipe manager for creating, saving and loading predefined factory settings

- Graphic user interface, recipe manager and quality report manager

The RTM X42.CC control center is an extension of the RTM X42 telemetry system. This extension provides easy-to-use tools related to wire voltage measurement and control management. Visualization of the measured data is an important function of the system and in addition to the setting and commissioning parameters, it is the Recipe Manager and the Quality Report Manager, where the generation of reports becomes a simple operation. The RTM Monitoring & Control software displays all relevant measurement and control parameters (only with RTM X42.BC Brake Control) at a glance. The recipe manager allows you to create, edit and save the appropriate RTM X42 settings for a specific product run and then load them later for identical product run. Thanks to this function, the process of setting up the machine is simplified and the quality of the product will follow when the process parameters are repeated. Using a network connection, the program can be run in any browser, independent of the main computer RTM X42

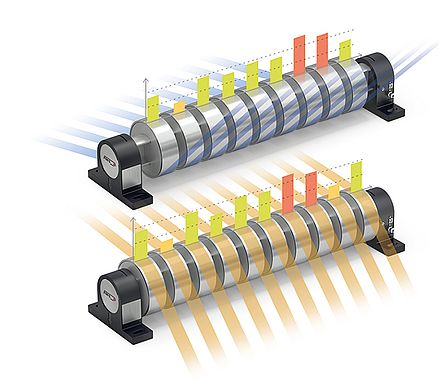

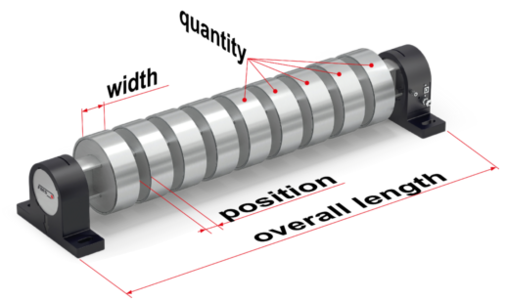

FMS-segFORCE - a new multi-point independent measuring cylinder

Thanks to its individual configuration and unique design, the FMS-segFORCE measuring cylinder can be successfully used in many different applications.

- quick identification of faulty windings or differential shafts

- clear display of the voltage value of each individual web section

- the highest flexibility in terms of number, width and spacing of segments

FMS Force Measuring Systems AG

New product group

Products of the company include

- sensors and amplifiers for measuring the strength of materials

- control cards for controlling tension in material

- Systems of guidance material

- wireless systems for monitoring tension in the materials (fibers, wires)

Products Company can be found in the following areas

- processing of materials in rolls "CONVERTING"

- production of cables and wires

- Manufacture of basic metals

- paper industry

- textile industry

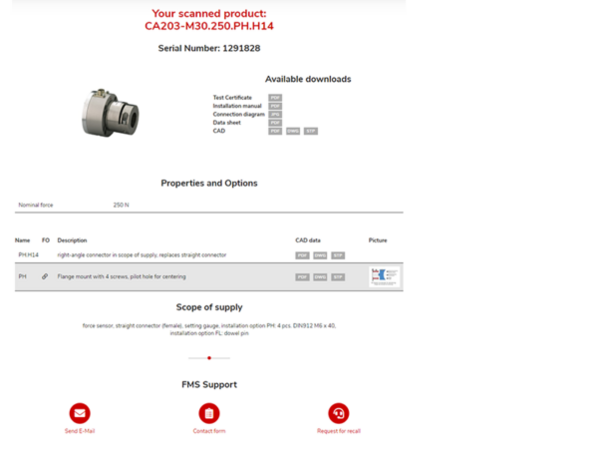

The application possibilities of QR codes

The application possibilities of QR codes have significantly increased in recent years. Especially with the widespread use of smartphones and the global data network, QR codes are seemingly everywhere

In order to provide fast and accurate product information during:

- Product installations

- Putting the machine into operation

- Maintenance / spare parts needs

FMS has implemented the FMS-QR-Code-Portal for you to better meet these important requirements.

Contact FMS for more information.

FMS QR Portal. Facts.

Where can I find the FMS-QR-Code?

The FMS-QR code can be found on the nameplates and packaging of all FMS force transducers and is already valid

Do I need to create an account to access the portal?

The data is accessible without registration, just scan the FMS-QR code. Because it is a web solution, no application installation is required.

What information can I get after scanning?

If you scan the FMS-QR code, you will be taken to the information page of the respective product. Here you can get:

- Strain gauge test report

- General product information

- Name, nominal force, description of the possibility, scope of delivery, etc.

- Product operating instructions

- Product manual

- Product drawing (with options, if available)

- Information on suitable accessories (eg rolling bearings)

- As well as the entire scope of delivery

FMS-QR-Codes and FMS-Sensors

The unique assignment of serial number information is only available for original FMS products

Closed loop control

- The sensor senses the position of the material

- material management controller calculates the deviation from the reference position and controls the actuator accordingly swing frame

- Actuator swing frame keeps the position of the reference material placement

BKS 309.EIP EtherNet / IP Material Controller

The BKS 309.EIP Material Controller is an innovative extension of the successful BKS 309 Series. With the integrated EtherNet / IP bus system, this system is extensively upgraded. This allows you to attach your material controllers to the higher level control or guidance elements. The control units can be combined with all rotating frames, control units and FMS assortment sensors.

Main features | Advantages |

| Integrated EtherNet / IP Bussystem | It enables the integration of the material control regulator to higher level control systems |

| Fast transfer rate with cycle times up to 2ms | Ideal for use in automated production lines |

| Clear display control with two-line display | Simple operation |

| 3rd types of driver body design | Available for wall mounting (IP65), DIN rail and built-in version. |

Motorized Sensor Adjustment BKS.TA

The BKS.TA is a series of motorized traverses designed to align precisely the material sensors on steering frames via an operation panel. One motorized sensor adjustment is required per sensor.

| Features | Advantages |

| Remote-controlled sensor adjustment | Allows precise sensor adjustment also in inaccessible places |

| 4 types with adjustment ranges of 200, 400, 600 and 1000 mm | Sensor positioning over the entire web width. Adaptable to any frame size. |

| Stepper motor / threaded spindle | Backslash-free, highly accurate positioning |

| Rugged design in aluminium profile | Long-lasting reliability, maintenance-free |

FMS - webMASTER and webDIRECTOR

Material management system FMS is mounted as close as possible to where accuracy is required. The FMS system-webmaster would swing frame length (L) should be the same as the maximum material width (Mmax). For optimum control of the sensor sensing the position of the material is mounted as close to the outlet of the rotary frame. The FMS system-management material WebDirectory will take place through a virtual turning point swing frame.

FMS - winderGLIDE

Actuators Board FMS-winderGLIDE have been specifically designed for use in unwinding and winding stations. Leveraging powerful drives are suitable for moving large rolls and stands. Sensor sensing the position of the material is mounted in the nearest tensioning cylinder. Use of electric drive actuators FMS versus hydraulic unit is favorable especially in food processing and pharmaceutical packaging, because here there is no contamination from oil and hydraulic fluid.

Maintaining a constant tension by the company products FMS

Winding / unwinding, coating, printing, and many other manufacturing processes require constant stress the material.

While addressing actuators, sensor technology, bus systems and amplifiers, the control voltage became necessary technologies required in the manufacturing process and process film, metal, paper and wire.

Nowadays, the load cells to measure stress (strain gauges) part of the standard equipment lines for materials in rolls.

Closed principle of voltage control "Closed loop tension"

- The sensors measure the actual voltage values of both voltages.

- Voltage regulator amplifies the measured signal from the strain gauge and calculates the output value of the difference between the reference and actual.

- The drive, brake, or clutch converts the output value of the voltage regulator to the corresponding torque or speed The.

- In the processed material will be kept notes sett ..

Advantages:

- defined, adjustable tension material;

- reproducible values to physical units (Newtons, pounds, etc.);

- Known manufacturing conditions for finished products (quality recording capability).

Strain:

Operational reliability and accuracy of measurement determine the productivity and quality of workmanship. Type of processed material and other factors, such as temperature, humidity and changing winding diameter, result in constant voltage variations in materials processing - without closing voltage control. FMS strain gauges measure and transmit a signal proportional to the voltage to the FMS electronic units. Individually tested FMS strain gauges are characterized by their ability to withstand extreme overload while maintaining maximum accuracy in the industry.

This is achieved through integrated mechanical knobs for overload protection and use of foil strain gauges which are connected as a Wheatstone bridge in each sensor to ensure the highest possible measurement accuracy. The sensors must be designed for each application separately and FMS to this end, provides a wide range of sensors. Calculation can be converted easily with the calculation program.

RTM: Wireless transmission voltage monitoring

Innovative Systems RTM evaluated data on stresses in individual strands of ropes or cables during stranding machines for processing. The load button is used for each source to obtain the actual voltage values and the corresponding data are then transmitted in real time from the rotating parts of the machine on a fixed surface. Transmission of wireless signals using public 2.4 GHz frequency band, while custom-coded protocols ensure high reliability and security, thereby eliminating the need for costly and problematic slip rings. Sophisticated and flexible interface concept allows quick and easy integration into existing control and communications infrastructure equipment. The RTM is available in various configurations, so you can choose the most appropriate option that best meets the requirements to collect data when upgrading existing stranding machines.

If the old machine is fitted with a power supply rotating section, are available rechargeable batteries. This makes the RTM systems optimized for low power consumption, and on battery power, it is possible to extend the operating time. The system provides an ideal basis for effective management of costs and quality as in the manufacture as well as for manufacturers of machinery.

Load cells calibrated for voltage measurement are located on the rotating part of the machine. Signals from up to 40 channels-ers are collected in a central unit that transmits to a receiver on the static side. The receiver processes the signals and depending on individual requirements, providing analog signals on the bus or on the computer screen of the corresponding software.

There are various systems adapted for the respective types of stranding machines. One system allows you to measure voltage up to 42 individual strands-oh. For machines with a large number of sources, it is possible to combine multiple systems. All signal processing options described above are available on our website. There is also a version of the battery.