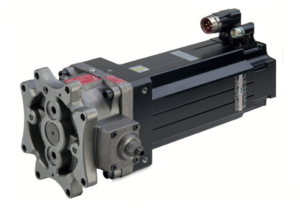

Moog's new modular electrohydrostatic drive (EAS) combines the best of two worlds: electrohydraulic (EH) and electromechanical (EM) drive

Advantages of modular EAS:

- High performance and power density in a compact and powerful alternative to EH and EM drives

- Environmentally friendly thanks to up to 90% lower oil consumption compared to standard systems and low noise emissions for quiet machine operation

- Small number of components reduces the risk of failure and enables faster maintenance

- Decentralized system does not require a large hydraulic unit and reduces the need for piping 2/3

- Technology for four-quadrant operation enables universal spectrum of use even in demanding applications and efficient energy management by means of energy recovery

- Low moment of inertia of the electrohydrostatic pump unit (EPU) ensures high system dynamics

Applications:

Modular EAS is suitable for a wide range of industrial machines. It can be used in metal presses, such as forging, powder and sheet metal presses up to hot presses, stamping presses and isostatic presses. In wood and paper milling, testing and power generation, the modular EAS enables improved decentralization of the machine axes. Other high-performance applications can be found in the marine industry, in the mobile machinery and in the plastics industry in injection molding and blow molding. The system reduces the need for oil for hydraulic units by 50 to 90%, which significantly reduces the operating costs of the machine.