Built-in logic valve of the slide type SL2H-CP3

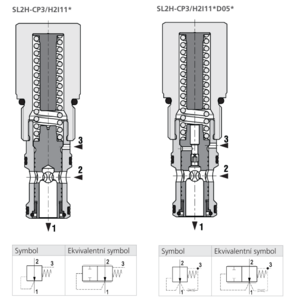

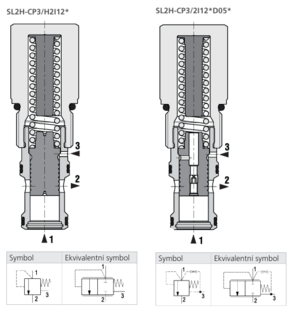

The built-in logic valve of the slide type SL2H-CP3 is manufactured in two versions:

- H2I11 – normally open – for two-way pressure balance applications (flow stabilization), or as a power stage of a two-stage pressure reducing valve

- H2I12 – normally closed – for two-stage relief valve or sequence valve power stage applications

Both versions are for a maximum flow rate of 120 l/min and a maximum pressure of 350 bar with a 1 1/16-12 UN thread.

Basic features

- large volume flow

- fast and smooth response to load changes

- stable function over the entire flow range

- precisely manufactured and hardened main parts

- precise adjustment of the pressure drop by an adjusting screw

- in the standard version the valve surface is galvanized with corrosion protection of 520 h in NSS according to ISO 9227

Technical parameters

- maximum flow rate up to 120 l/min

- five spring preload settings from 3 to 20 bar for H2I11 and 6 preload settings from 0.5 to 20 bar for H2I12

- manual preload adjustment option in the range of 10 to 100% of the selected pressure range

- maximum working pressure up to 350 bar

- internal supply or external control pressure supply

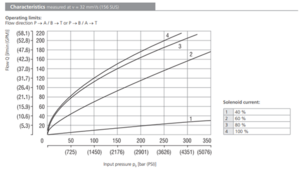

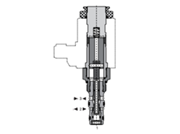

We are pleased to introduce the new built-in proportional pressure relief valve SR4P1-C2.

The valve consists of a control stage - valve

SR1P2-A2 and a main stage with a connecting thread 1-1/16-12 UN.

Technical parameters

- Valve connection thread / chamber 1-1/16 12 UN / C2

- Maximum flow rate 200 lpm (53 GPM)

- Maximum pressure 350 bar (5100 PSI)

- Zinc plating durability 520 h in NSS (according to ISO 9227)

- Fluid operating temperature range -30…+120 °C

Benefits

- Built-in SIC valve design makes installation easier

- Low hysteresis, precise pressure control and low pressure losses

- Large inlet pressure range up to 350 bar

- High volume flow rate up to 200 l/min

- The pressure in the circuit increases proportionally with increasing electrical control signal

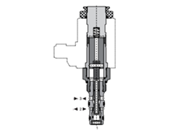

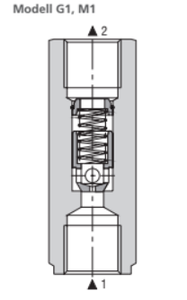

New built-in relief valve- SR1A-CA2

We are pleased to introduce the new built-in pressure relief valve, directly operated with excellent stability, SR1A-CA2.

The valve is characterized by very high performance and is designed to set the maximum pressure in the circuit and to protect the hydraulic circuit against overload.

Technical parameters

- Valve connection thread / chamber 1-1/16 12 UN / CA2

- Maximum flow rate 120 lpm (32 GPM)

- Maximum pressure 350 bar (5100 PSI)

- Zinc plating surface protection durability 240 h in NSS (according to ISO 9227)

- Fluid operating temperature range -20…+90 °C

Benefits

- Optimal price due to simple design of the directly operated valve

- Built-in SIC valve design facilitates installation

- The seat valve design principle guarantees low volume losses of the closed valve

- Stable function over the entire flow range with fast response to pressure changes

- Low maintenance costs due to the valve's resistance to failures

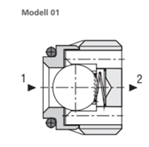

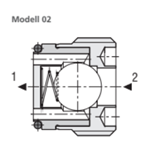

SFD2F – Flow dividers / combiners

ARGO-HYTOS offers flow dividers / combiners in cartridge design. Currently, there are two versions on offer:

- SFD2F-B4/E for flow rates up to 45 l/min for mounting in a cavity with a 7/8-14 UNF-2A thread

- SFD2F-D4/E for flow rates up to 170 l/min for mounting in a cavity with a 1-5/16-12 UN-2A thread

These flow dividers:

- are designed to divide the flow rate from the hydrogenerator to the consumers to ensure synchronization of movements regardless of the load

- are designed for controlled merging of flows from the consumers towards the tank

- have high division / merging accuracy ±10%

- in the standard version they have high corrosion protection of 520 h in NSS according to ISO 9227 (in the standard version the valve surface is galvanized)

Technical parameters

- maximum flow rate up to 45 l/min (SFD2F-B4/E) in four ranges, respectively up to 170 l/min (SFD2F-D4/E) in two ranges

- maximum working pressure up to 350 bar

- dividing / combining accuracy ±10%

- dividing ratio 1:1

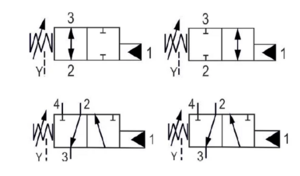

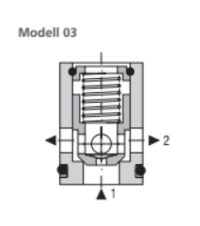

SD6H-AY3 and SD6H-AY4 – hydraulically controlled 2/2 and 3/2 distributors

ARGO-HYTOS presented new, hydraulically controlled switchgears in cartridge design.

These are:

- 2/2 hydraulically controlled distributor SD6H-AY3

- 3/2 hydraulically controlled distributor SD6H-AY4

Technical parameters

- maximum flow rate up to 30 l/min

- maximum working pressure up to 350 bar

- two ranges of control pressure 10...60 bar and 35...130 bar

- cartridge design with 3/4-16 UNF connection thread

- external leakage from the spring space

- anti-corrosion treatment 240 hours NSS according to ISO 9227

- working temperature range -30...120 °C

Advantages

- no external electrical control is required

- space-saving valve

- long service life

Efficient and reliable control of hydraulic systems with poppet valves

ARGO-HYTOS poppet valves offer precise control and high reliability in hydraulic systems. Thanks to their robust construction and minimal leakage losses, they are suitable for applications requiring high operating pressures and precise control. Seat valves enable particularly efficient energy transfer, reduce wear and extend the life of your hydraulic systems.

Whether in mobile machines or industrial applications: High-quality poppet valves from ARGO-HYTOS increase the performance and efficiency of your equipment. Find out all about the technical advantages of poppet valve technology in this article.

How are poppet valves technically designed?

Poppet valves consist of a housing, a valve seat, a spring and a movable valve element. The cover protects the internal components from external influences. The valve seat acts as a sealing surface that regulates fluid flow. These components ensure a reliable seal and prevent fluid from flowing through the valve when it is closed.

The movable valve element - often in the form of a cone or ball - is operated by a pressure difference and a spring. When closed, the spring pushes the valve element against the seat, cutting off flow.

If the pressure in the system exceeds the set value, the force of the fluid acts against the spring. This raises the valve element, allowing fluid to flow.

The function of poppet valves is based on the precise movement of the sealing element. When opened, the element moves away from the seat to release the flow. When the pressure in the hydraulic system drops, the valve element returns to the closed position by spring force. The force of the spring ensures that the valve responds quickly and reliably and cuts off the flow when necessary.

ARGO-HYTOS poppet valves are designed to handle high operating pressures and at the same time enable precise liquid flow control. The choice between a poppet and a ball valve depends on the specific application. Cone poppet valves ensure better sealing at higher pressures, while ball poppet valves are particularly easy and reliable to use.

What are the characteristics of different poppet valves?

Poppet valves come in a variety of designs, each offering specific applications and benefits. The most common types are ball poppet valves, cone poppet valves and disk poppet valves.

Advantages of ball valves:

Ball poppet valves use a ball as a sealing element. The ball prevents fluid backflow by being forced against the seat by fluid pressure. This design is often used in non-return valves, where it reliably prevents the backflow of liquids. Ball poppet valves are particularly robust and can work effectively under various conditions, as the ball fits easily into the seat.

They are easy to make and therefore cheap.

They are particularly effective as a check valve. The ball is firmly pressed against the seat by the pressure of the fluid and thus prevents backflow.

Due to their simple design, ball valve valves are resistant to pollution and mechanical stress.

Advantages of conical poppet valves:

Cone poppet valves have a ground, guided cone sealing element that allows for a very precise seal. This design requires a high degree of precision in the manufacture of the cone to ensure an optimal seal. Due to their versatility, poppet valves are often used as relief valves, check valves or directional valves. They offer excellent tightness and are ideal for applications that require precise flow control.

Advantages of disk disc valves:

Disc valves operate using a plate sealing element with a small stroke range and a large cross-section. These valves are intended for applications in the low pressure range. They are often used as shut-off valves or for simple pressure regulation - for example in filter elements. The cross-section allows high flow with minimal pressure loss.

- Large cross-section allows high flow at low pressure. This is ideal for applications with low pressure requirements.

- Plate design allows for a small stroke range, making it easy to use in applications with limited space.

- These valves are suitable for applications such as filter elements where simple and cost-effective pressure regulation is required.

What makes poppet valves efficient and reliable?

Poppet valves provide a positive and non-positive seal that completely prevents leakage. This feature eliminates the need for additional oil escape lines and maximizes system performance.

Due to their design, poppet valves open immediately after activation and have a short stroke, resulting in a fast response time. This is particularly useful in applications where fast control is required - such as high-speed machines and precision control applications. The simple design of poppet valves results in low costs in relation to a long service life.

Thanks to their design, poppet valves are less susceptible to contamination. The basic design minimizes the ingress of particles, which reduces maintenance requirements and extends the life of the valve.

Poppet valves are often designed as pilot-operated valves, allowing them to operate with lower actuating forces. This feature reduces power consumption and allows the use of smaller controls. The long service life of poppet valves helps minimize downtime and ensures operational safety.

Disc valves from ARGO-HYTOS

ARGO-HYTOS offers a wide range of poppet valves that meet various requirements in hydraulic systems. Available valve types include directional control valves, non-return valves, non-return valves, throttle valves and pressure relief valves. These valves are available in both direct and pilot operated versions. Depending on the requirements, the valves can be used as screw-on or modular valves.

The valves are controlled either magnetically or hydraulically - depending on the specific application. For special applications, ARGO-HYTOS also offers valves that are suitable for potentially explosive environments. These valves are certified according to ATEX/IECEx standards and offer maximum safety in demanding environments.

The selection and sizing of valves depends on the specific requirements of the application. These include pressure range, volume flow and mode of operation (normally open or normally closed). For applications that require precise control and high flow capacities, we recommend using valves with a particularly fast response.

Areas of application of ARGO-HYTOS poppet valves

Valves from ARGO-HYTOS are used in many applications. In mobile machinery such as excavators and rollers, poppet valves provide precise control of hydraulic systems that perform lifting and lowering movements. In agricultural vehicles, including tractors and pick-up trucks, poppet valves ensure even power transmission. They thus help to optimize fuel consumption.

In municipal utility vehicles used for maintenance and road cleaning, poppet valves control complex hydraulic systems. Poppet valves are also essential in industrial applications. In injection molding machines, they ensure precise movement sequences or provide stable pressure regulation in hydraulic presses. In CNC machines, they contribute to the precise positioning of tables and machine axes.

Find out more about poppet valves from ARGO-HYTOS

ARGO-HYTOS poppet valves are an efficient and cost-effective solution for a wide range of hydraulic applications. Their robust construction and ability to handle high pressures and flows make them a valuable part of modern hydraulic systems. By combining precise control, minimal leakage and fast response time, poppet valves help optimize system performance. They also reduce operating costs.

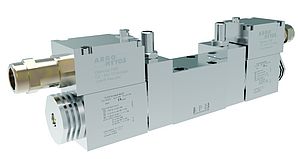

ARGO-HYTOS : Hydraulic valves for hazardous areas

Hydraulic systems must function safely and reliably in potentially explosive areas. For more than ten years, ARGO-HYTOS has been offering safe EX valves for mines, chemical or petrochemical plants, as well as dusty areas prone to explosion.

The valves are designed according to the explosion protection class EPL b. This corresponds to a "high" level of protection for use in particularly hazardous areas where there is a possibility of ignition during normal operation or foreseeable malfunctions.

Explosion-proof spool operated valves are available in the market in different versions. Each of them consists of an electrical part, an electromagnet control coil, and a mechanical part that includes a control system and a hydraulic part.

The basic protection of the electromagnet coil is encapsulation with insulating material (protection class m, EN 60079-18). The terminal box for electrical connection of the coil as well as the cable gland are certified according to e (EN 60079-7). Our EX valves are certified for explosion-prone areas with hazardous dust according to protection class t (EN 60079-31).

The coils themselves are certified according to the European directive 2014/34/EU and internationally valid IECEx as well as other national standards.

The rated power is related to the maximum surface temperature of the coil, which is in turn divided into classes: valves with a 10 W coil can be used in temperature classes T4 (135 °C), T5 (100 °C) or T6 (85 °C), provided that power supply, ambient temperature and fluid temperature specifications will not be exceeded. The 18 watt variant can only be used in class T4 due to higher power dispersion.

Valves can be equipped with manual emergency control in case of coil or power failure. Manual control can be controlled up to a pressure of 25 bar in the control system. The coil-operated directional control valve with built-in manual control enables operation at pressures of up to 100 bar on the T-port. This does not affect normal coil control.

Advantages:

- Explosion-proof operation

- Certified according to international standards

- Flexible power supply

- Corrosion resistant

- Not susceptible to mechanical stress

- Can be used in harsh conditions in mines

Argo-Hytos customer applications.

Argo-Hytos customer applications, whether for mobile machines or stationary devices, must comply with high requirements for compactness, modularity, easy controllability of components, as well as energy efficiency of hydraulic systems.

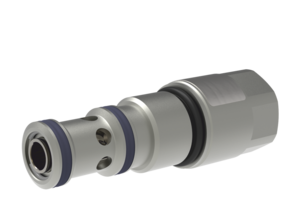

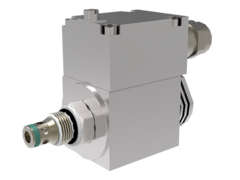

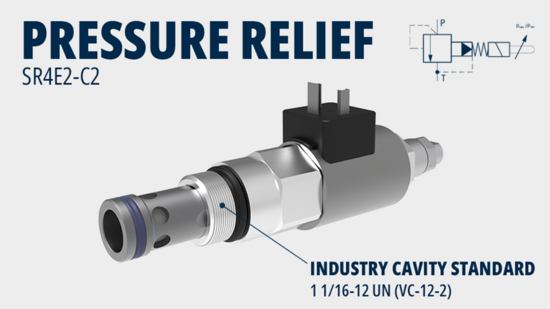

ARGO-HYTOS : Pressure relief valve SR4E2-C2

We present to you the new SR4E2-C2 pressure release valve with excellent stability in the entire flow range up to 180l/min.

The picture will help to better identify the functionality of this valve:

Technical parameters

- Connection thread 1 1/16-12 UN (VC-12-2)

- Maximum flow rate up to 180lmin (48 GPM)

- Maximum pressure up to 350 bar (5100 PSI)

- High level of anti-corrosion protection 520h SST (according to ISO 9227)

- Working temperature of the liquid -30...+80°C

Benefits and advantages

- Excellent stability in the entire flow range up to 180 l/min

- Low hysteresis and precise pressure control

- Easily replaceable electromagnet coil and easy positioning of the connector

- Possible combined function of pressure release and relief valve

- Remotely controlled switching between the set minimum and maximum pressure values using a control electromagnet

- Elimination of pressure peaks in case of a significant change in flow rate

- Extremely low pressure drop for high flow rates

- Its function has an effect on the longer service life of the hydraulic drive

- Lower final costs for assembly and operation

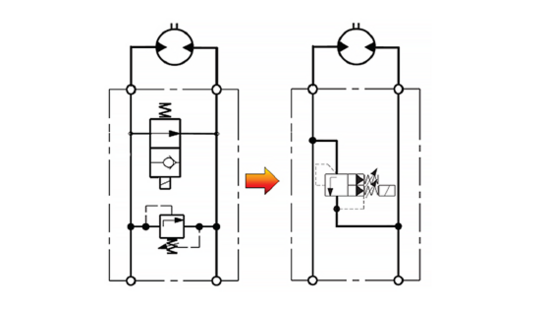

Example of use

Pump relief

The valve is used to relieve the pump - connection with the tank at a low pressure loss. This solution reduces the heating of the working fluid and the cost of the input energy of the system.

First, the max. must be set. pressure p1 and then min. pressure p2. Setting the maximum pressure is possible with an activated electromagnet using a screw with a socket for a size 10 key. Setting the minimum pressure is possible with a deactivated electromagnet using a screw with an internal 6HR 3.

For more information regarding the new SR4E2-C2 pressure relief valve, visit our site at this link.

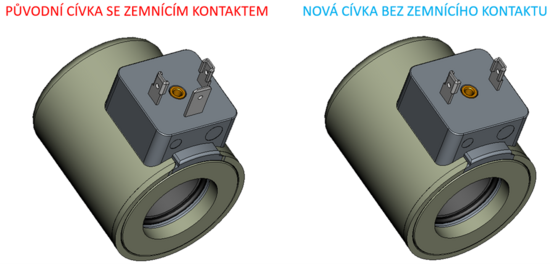

ARGO HYTOS change of coil production

ESCRIPTION OF THE CHANGE:

Coils of all sizes (C14B, C19B, C22B, C31A) with E1 and E2 connectors (EN 175301-803-A) with a DC supply voltage of up to 60 V will be supplied with only two supply contacts as standard, and the grounding contact will no longer be standard in these coils. Deliveries of coils with a grounding contact will continue to be possible, but they will be for an additional fee determined by the price list (see the price list chapter). Coils without a ground contact will also automatically be used in all affected solenoid operated valves. The hydraulic characteristics of the valves will not be affected by this change.

Coils with a DC supply voltage above 60 V will continue to be supplied with three contacts (two supply contacts and one ground contact) and will be for an additional fee (see the price list chapter). Coils with AC supply voltage (connectors E5 and E51) or coils for explosive environments will not be affected by this change.

PRODUCTS:

Removal of the grounding contact refers to:

- coils of all sizes (C14B, C19B, C22B, C31A) with E1 and E2 connectors (EN 175301-803-A) with DC supply voltage up to 60 V

- all electromagnetically controlled ON/OFF + proportional, CETOP + CARTRIDGE valves in which these coils are used (note: for built-in SD and ROE valves, the spool is ordered separately as standard)

- blocks and aggregates in which these coils and valves are used

This change does not apply to:

- coil with alternating supply voltage (connectors E5 and E51)

- coils for valves with CSA certification

- coils into an explosive environment

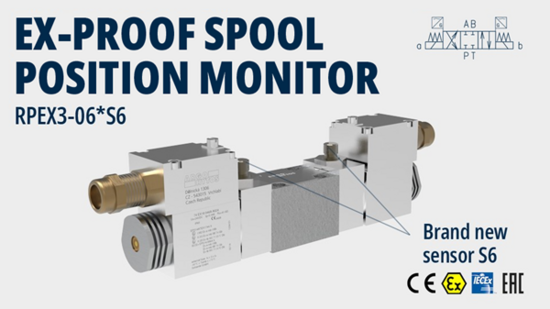

ARGO-HYTOS : Radial blade position sensor for RPEX3-06*S6

We make your products better. Worldwide.

The company ARGO-HYTOS informs about the latest modernization of the valve for environments with the potential for explosion RPEX3-06*S6.

A completely new S6 radial blade position sensor that has many new features and benefits compared to the old one, such as more classes and groups for hazardous areas, including expanded certifications.

Technical parameters

- ATEX electromagnet coil certification according to Directive 2014/34/EU and IECEx according to OD 009 IECEx for potentially explosive environments

- Non-contact induction sensor for indication of reaching the end position of the blade

- Reduction of the dependence of the hydraulic performance of the valve on the viscosity of the liquid by using a five-chamber body

- Design limiting the temperature of the electromagnet prevents ignition

- High transmitted hydraulic power, maximum pressure up to 350 bar while maintaining low pressure loss by using a high flow body

- A large selection of shutter connections and emergency manual controls

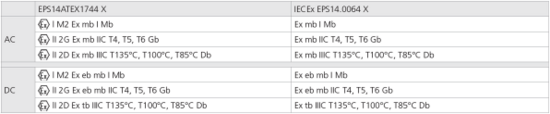

ATEX / IECEx Certification

Usage details

Variants of certified control electromagnets and position sensors for valves intended for environments with different risk of explosion:

Logic valve SL2H-BP3

We are pleased to announce the expansion of our product portfolio to include products from the line of logic valves.

Technical parameters

- The valve maintains a constant pressure drop across the valve for flow control (e.g. proportional distributor) and thus a constant volume flow independent of changes in the load of the appliance

- Connection thread 7/8-14 UNF (C-10-3S)

- Maximum flow rate up to 80 l/min (21 GPM)

- Maximum pressure up to 350 bar (5100 PSI)

- High level of anti-corrosion protection 520h SST (according to ISO 9227)

Benefits

- High volumetric flow rate

- Fast and smooth response to load changes

- Stable function in the entire flow range

- Precisely manufactured and hardened key parts

- Setting the pressure drop with the adjusting screw

- Function of a two-way pressure balance or the main stage of an indirectly controlled reducing valve

- Working temperature of the liquid -30...+120° C

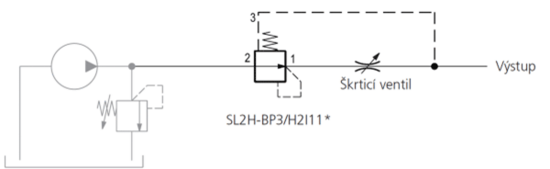

Example of use

Stabilization of pressure drop

The logic valve stabilizes the pressure drop on the flow control valve and thus ensures the independence of the volume flow from changes in the load on the appliance or from fluctuations in pump pressure. The position of the scale scale is controlled by the difference in pressures sensed before the valve (1) and after the valve (3). The pressure drop is given by the pressure of the spring on the face of the blade and is stabilized by throttling the flow (2 → 1) with the blade.

In the basic position, the logic valve is open. The flow, and thus also the speed of movement of the output member of the appliance, can be continuously controlled by changing the flow cross-section of the flow control valve or by changing the pressure drop on the logic valve using the adjusting screw.

The logic valve is connected between the pump and the flow control valve (input connection) if the load force is positive, i.e. in the direction against the movement of the output member of the appliance.

Indirectly controlled proportional switchgear

We are pleased to present our new indirectly controlled proportional spool valve PRM8 in size NG10 (CETOP05) with high transmitted hydraulic power.

Technical parameters

- Pressure range up to 350 bar (5080 psi)

- Flow rate up to 210 l/min (55.5 gpm)

- Standard version of coils size NG06 (CETOP03)

- Wide range of connection connector types

- Optional types of manual switchboard control

- High level of surface protection by galvanizing up to 520 h. SST (according to ISO 9227)

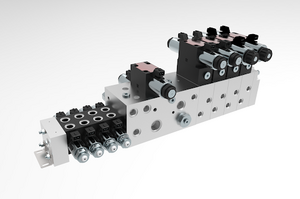

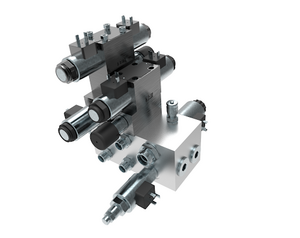

ARGO HYTOS valve blocks

Valve blocks consist of a large number of integrated valves such as relief valves, directional control valves and pressure control valves. They are placed in one case. This compactness facilitates assembly, reduces leakage points and enables optimized hydraulic flow.

What are the main technical characteristics of valve blocks?

- they reduce the susceptibility to leaks and increase the reliability and tightness of the system.

- they facilitate assembly, save space and increase the overall efficiency of the system.

- They thus increase the efficiency and performance of machines and systems by enabling precise control and regulation of hydraulics.

- they reduce maintenance and operating costs.

Valve block materials

- The steel offers excellent strength properties and is suitable for high pressures up to 420 bar.

- Cast iron provides a good balance of strength and cost effectiveness for similar pressure ranges up to 420 bar.

- Aluminum is lighter and suitable for applications with pressure up to 250 bar.

Different types and designs of valve blocks

- Monoblock: they are made of one piece and provide a compact and robust solution. They are ideal for applications with limited space and are particularly suitable for smaller systems.

- Connecting plates or control plates: Their design allows easy mounting of valves and connections directly on the plate.

- Longitudinal or vertical connection: In these designs, valves and connections are connected either longitudinally or vertically. Linked settings enable optimized valve arrangement and efficient use of available space.

What are the applications for valve blocks?

- Stationary, industrial machines and devices

- Mobile machines

- Agricultural, forestry, construction machinery and equipment.

Product benefits:

- The valve ensures the sequence of movements of the hydraulic actuators

- Limits the maximum pressure in the circuit and thus protects the circuit against pressure overload

- Integrated bypass one-way valve prevents cavitation

- External drainage of the spring space through channel 3

- The pressure in channel 2 does not affect the opening pressure of the valve

- The valve can be adjusted even while the device is in operation - sealed adjustment element

- Long service life with a guarantee of > 10 million cycles for an operating pressure of 420 bar

- Low energy consumption

Technical parameters

- standard versions of the chamber 7/8-14 UNF (C-10-3S)

- Volume flow up to 40 l/min (11 GPM)

- Pressure up to 420 bar (6100 PSI)

- Wide range of adjustment of the opening pressure of the sequential valve up to 420 bar (6100 PSI)

Argo-Hytos

Built-in valves for industrial use

Switchboard:

- Design for gate valves or poppet

- Two-position and three-position

- 2, 3, 4-way distributors

- Single-stage (direct control) and two-stage (indirect control with control stage)

- Manually operated hydraulic, pneumatic, electric

- Built-in (cartridge) or mounting plate (CETOP)

- Selected distributors in versions for explosive atmospheres (ATEX)

One-way valves:

- Unidirectional logical three-way valves

- Selection valves

- One-way valves

- One-way valve with bypass

- Hydraulic locks - controlled opening

- Hydraulic locks - controlled closure

And pressure reducing valves:

- Directly managed Bypass valves

- Nepriamoriadené bypass valves

- Reducing valves directly managed

- Nepriamoriadené reducing valves

- Safety valves with bypass

- Sequence valves

Butterfly valves:

- Built-in butterfly valves

- Butterfly valves in modular design

- Two-way flow control valves with pressure gradient stabilization

- Three-way butterfly valves with the stabilization of the pressure gradient

- Dividers and connectors Flow

Brake valves:

- Triggering brake valves

- Triggering brake valves, partly independent of the dynamic pressure

- Triggering brake valves, completely independent of the dynamic pressure

- Triggering brake valves, quite balanced, with internal drainage

Proportional technology:

- Proportional distributors for installation on board brightness NG4, NG6 and NG10

- Directly controlled bypass solenoid actuated proportional valves

- Indirectly administered by the overflow solenoid actuated proportional valves

- Directly controlled proportional solenoid reducing valves

- Indirectly controlled by reducing solenoid actuated proportional valves

- Two-way pressure regulator

- Three-way pressure regulator

- Electronics for control proportional valves

Connecting rods and blocks:

- Terminal Connecting plates

- Convection built-in valves

- Cover plates

- Connection board

- Adapter plate for built-in valves

NEW TYPES of enclosures for directly controlled 4/3 switchgear

We are pleased to announce the expansion of the available enclosures for our new directly controlled 4/3 switchgear.

A new H11 and C11 shell is available.

Product benefits:

- High hydraulic performance in a compact design

- Energy saving up to 20%

- Ports 2, 3, 4 can be loaded with a pressure of 350 bar (5080 PSI),

- port 1 up to a pressure of 250 bar (3,630 PSI)

- Low pressure losses

- 4 types of shells

- C19B* coil interchangeable within the SD*-A*/H* product line

- Emergency control with locking in both extreme positions without the need for tools

- Lifetime guaranteed up to 10 million cycles

- Higher hydraulic performance and lower pressure loss than competitive solutions

Technical parameters:

- Flow rate up to 30 l/min (7.9 GPM), working pressure up to 350 bar (5080 PSI)

- Standardized chamber 3/4-16 UNF (C-8-4)

- HNBR seal (liquid operating temperature range -30 … +80°C)

- FPM seal optional (liquid operating temperature range -20 … +80°C)

- High level of surface protection by galvanizing according to ISO 9227 (durability 520 h)

SD3EX-C2*S5(S6)

ARGO-HYTOS: NEW saddle, indirectly controlled, 2/2 distributor

We present to you a new saddle-type, indirectly controlled, 2/2 built-in distributor, intended for environments with a risk of explosion, characterized by excellent tightness in both directions.

Benefits

- Two-way tight valve

- Ex, IECEx, ATEX certification according to directive 2014/34/EUa

- Extremely high hydraulic performance

- All channels can be pressurized

- Flow rate up to 150 l/min, working pressure up to 350 bar

- Normally closed (2S5) and normally open (2S6) variant

- A wide selection of emergency controls, mainly for the S6 connection

- Lifetime guaranteed up to 10 million cycles

Technical parameters

- Flow rate up to 150 l/min, working pressure up to 350 bar

- Standardized chamber 1-1/16-12 UN

- EX, IECEX, CE, EAC certification

- NBR seals (liquid operating temperature range -30 ... +80°C)

- High level of surface protection by galvanizing according to ISO 9227 (durability 520 h)

SD3E-C2*S5(S6)

Indirectly controlled 2/2 saddle built-in distributor with high volume flow and excellent tightness in both directions

SD3E-C2*S5 ( S6 )

Available basic shell positions 2S5 (closed) or 2S6 (open).

Benefits:

- High tightness of the cone in both directions

- Extremely high hydraulic performance

- Flow rate up to 150 l/min, working pressure up to 350 bar

- Normally closed (2S5) and normally open (2S6) variant

- Coil interchangeable within the SD*-C/H* product line

- A wide selection of emergency controls mainly for connecting the S6

- Lifetime guaranteed up to 10 million cycles

Technical parameters:

- Flow rate up to 150 l/min, working pressure up to 350 bar

- standardized chamber 1-1/16-12 UN

- NBR seal (liquid operating temperature range -30 … +80°C)

- FKM seal (liquid operating temperature range -20 … +80°C)

- High level of surface protection by galvanizing according to ISO 9227 (resistance 520 h)

Voith Technology Group takes over ARGO-HYTOS.

ARGO-HYTOS – a company based in Baar, Switzerland, develops and manufactures hydraulic components and system solutions with a focus on the mobile hydraulics sector (agricultural tractors, road and construction machinery, etc.).

The underlying agreement was signed on June 6, 2022. The deal is expected to be completed in August 2022, subject to all regulatory approvals. Both parties agreed not to disclose financial details of the transaction.

Voith is a technological leader in drive technology in various industries. The mobile hydraulics sector has been defined as another growth area for Voith Turbo. With its more than 70 years of experience, its focus on technology and innovation, as well as its clear customer orientation, the family business ARGO-HYTOS is a perfect fit for Voith. This makes ARGO-HYTOS the ideal entry point for Voith into this promising market.

Voith will acquire 79.5% of ARGO-HYTOS shares through the acquisition. The continued participation of the two previous owners – Christian Kienzle and FSP CAPCELLENCE – gives a strong signal that ARGO-HYTOS will consistently and continuously continue on the successfully embarked path even with the new ownership structure.

4/2 electromagnetically controlled switchboard with axial encoder and functional safety certificate

Argo - Hytos presents you with an improved RPE3-062x / xS3 switchgear with axial encoder, new with TÜV SÜD certification!

RPE3-062x / xS3 *

Benefit

- High hydraulic power

- Low pressure losses

- Contactless inductive valve position sensor with double inverted output signal

- Wide selection of valve connections, supply voltage and coil connectors

- High level of surface protection by galvanizing according to ISO 9227 (resistance 520 h)

- Guaranteed service life of up to 10 million cycles

Technical parameters

- Maximum flow up to 80 l / min (21 GPM)

- Maximum working pressure up to 350 bar (5,080 PSI)

- NBR seals (for temperatures from -30… + 80 ° C)

- FPM seals (for temperatures from -20… + 80 ° C)

- Low sensor switching point hysteresis

Peter Lauko

Tel.: +421 37 7777 955

Mobile: +421 903 282 644

Fax: +421 37 7777 967

Email:lp@bibus.sk

Jaroslav Tvrdoň

Tel.: +421 37 7777 954

Mobile: +421 914 336 525

Fax: +421 37 7777 967

Email: tvr@bibus.sk

Vladimír Begáň

Tel.: +421 37 7777 954

Mobile: +421 914 336 527

Fax: +421 37 7777 967

Email:vbe@bibus.sk