MINIMUM SIZE – MAXIMUM POWER

The miniBOOSTER with integrated brake valve is designed to provide stability, safety and efficiency in hydraulic systems. The valve saves energy, speeds up the process and reduces wear, making it a more sustainable solution.

As always, miniBOOSTER ensures that you have access to the products you need, exactly when you need them. Our extensive warehouse allows us to ship most orders the same day, no matter where you are.

Key features of using a miniBOOSTER with an integrated brake valve.

The benefits of a booster with an integrated brake valve include:

- Increased efficiency (higher speed).

- Extended service life. The booster is only activated when needed, reducing wear and ensuring a longer service life.

A booster with an integrated brake valve allows for rapid forward movement of the cylinder by directing the full inlet flow to pass directly through the booster section until the set pressure is reached, also called the idle movement.

At that point, the brake valve opens and the booster begins to oscillate, facilitating a high-performance, two-speed, two-force solution. The booster speed is highest when it is not loaded. The integrated valve eliminates the phase in which the booster is most vulnerable, further increasing its service life.

Hydraulic System Applications

miniBOOSTER with built-in balancing valves are widely used in applications with large cylinders and long idle times.

Common applications include:

- Cranes and hoists

- Hook lifts

- Demining plows

- Large diameter pipe handling

- Swarf presses

- Industrial presses

Why choose miniBOOSTER?

Our boosters with brake valves are built with durability and precision in mind, giving you a reliable solution for your hydraulic systems. Whether you are handling cranes, mobile equipment or industrial presses, our valves provide the safety and control you need to keep your operations running smoothly.

MINIMUM SIZE – MAXIMUM POWER

miniBOOSTER celebrates its 30th anniversary this year.

Since 1994, miniBOOSTER has been a global leader in the development and production of hydraulic boosters.

As we enter our fourth decade, miniBOOSTER has transformed from a small manufacturer to a world leader in hydraulic boosters and booster systems. What a ride! We are very proud of what we have achieved in that time.

While it's fun to look back at what we've accomplished, we're firmly focused on developing, delivering and supporting new products to help our customers develop innovative and time-saving products and processes. We recently introduced our HC4H and HC6H boosters, which are capable of 3,000 bar (40,000+ PSI) to enable our customers in the bolt tightening industry to tackle larger projects cost effectively.

miniBOOSTER is constantly looking for ways to improve our products to help make your hydraulic system better, faster and cheaper.

We are very proud of our huge inventory of miniBOOSTER, which will get you the best product on the market within a few business days - anywhere in the world! We have it on the shelves!

Maximize strength and minimize weight and size.

miniBOOSTER increases the pressure in hydraulic devices.

We offer you more energy-efficient solutions combined with the practical advantages of lighter, stronger, more compact and faster tool solutions.

Tightening screws in wind turbines.

It should come as no surprise that miniBOOSTER is the booster technology of choice for the leaders in the bolt tightening industry. Today, screw tightening is synonymous with wind turbines.

Demanding applications such as screw tightening highlight the benefits of using the miniBOOSTER. Bolt tightening requires repeated and consistent cycling upwards of 1,500 bar (20,000+ PSI).

A team of experts. It starts with the depth of our knowledge base. There's a good chance we've "been there and done that" before. From concept to product support, miniBOOSTER has the resources to meet the needs of our customers.

Accuracy by design. Accurate tightening of several critical bolt assemblies is essential to ensure longer and safer turbine operation. Accuracy with the miniBOOSTER is precisely and repeatedly achieved by simply adjusting the input pressure to the amplifier.

Reliability by design. miniBOOSTER bolt-tightening boosters do not have dynamic seals to extend life and reduce maintenance.

Time is very important here. By design, miniBOOSTER amplifiers are up to 5x faster than other amplifier technologies.

You need it now! miniBOOSTER maintains a large stock of products. More than 90% of orders are shipped within 2-3 business days.

miniBOOSTER - portable multiplier M-HC7-DA

The portable multiplier M-HC7-DA is a robust unit designed to drive double-acting hydraulic cylinders with multiplication in both directions of movement. It is designed for the most demanding industrial applications. The inlet working pressure range is from 20 to 350 bar and the minimum flow is 2 l / min. The outlet pressure can reach up to 2000 bar in both directions of movement at a maximum flow rate of up to 40 l / min.

Reliability is a paramount aspect of design, so the M-HC7-DA is equipped with a 12-micron filter and a visual indicator of filter cartridge clogging. This extends service life and avoids unnecessary downtime.

Portability and ease of use - weighing only 14 kg and with a comfortable lifting handle, the M-HC7-DA can be easily transported where needed.

The M-HC7-DA is powered by an existing low pressure hydraulic source. No additional tools are needed. All controls are integrated into the unit and provide simple and reliable performance.

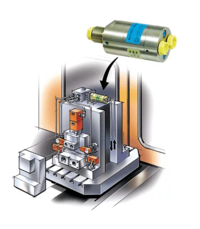

Promotional video - possibilities of using miniBOOSTER pressure multipliers in machine tools

The miniBOOSTER pressure multipliers are widely used in various industries - demolition technology, agriculture, oil and gas extraction.

Machining is one of the industries where pressure multipliers are very common. They are used here due to their small size, low weight, low operating and maintenance costs.

They are mainly used for:

- clamping of workpieces and tools

- locking the position of the tool

- tool release during tool change

- positioning of the working head

MINIBOOSTER - Multipliers HC25; HC75; HC65D-D with brake valves

The minibooster introduces new models of HC25, HC75 and HC65-D multipliers with integrated brake valves.

This new range of multipliers with built-in brake valves is a two-stage high-pressure solution - they reliably deliver full pump flow up to a set max. pressure and then the pressure booster is automatically activated, creating the required high pressure.

The pressure to start the multiplication is set at the factory, but can be easily adjusted in the field to suit the actual pressure of the drive pump.

The multipliers can be supplied in a pipe design or for board mounting.

The maximum pressure of the multiplier is 800 bar at a pump pressure of up to 210 bar and a pump flow of up to 80 l / min. There are a large number of amplification factors to choose from, from 1.2 to 25.

MINIBOOSTER - Pressure boosters

They are used to increase the low pressure inlet to the required level (up to 2000 bar).

Compared to the standard high-pressure systems have the following advantages:

- Higher efficiency and longer service life of the system (operating at lower pressure).

- Compact system.

- Increase safety (reducing the high pressure part).

- Integrated valves.

- No dynamic seals.

- Boost pressure ratio adjusted to the current requirements.

Common applications:

- Hydraulic clamping tools.

- Injection-molding machines: clamping molds, core pulling.

- Hydraulic tools: scissors, clamps ...

- Torque wrench.

- Connectors for turntables.

- Test equipment (up to 3000 bar).

- Scissors concrete.

- Aggregates.

Promotional Video - Possibilities of utilizing miniBOOSTER pressure multipliers in industry

Promotional video - Possibilities of utilizing miniBOOSTER pressure multipliers in agricultural applications

Peter Lauko

Tel.: +421 37 7777 955

Mobile: +421 903 282 644

Fax: +421 37 7777 967

Email:lp@bibus.sk

Jaroslav Tvrdoň

Tel.: +421 37 7777 954

Mobile: +421 914 336 525

Fax: +421 37 7777 967

Email: tvr@bibus.sk

Vladimír Begáň

Tel.: +421 37 7777 954

Mobile: +421 914 336 527

Fax: +421 37 7777 967

Email:vbe@bibus.sk